It is National Pizza Day today, and the Paper and Paperboard Packaging Environmental Council (PPEC) wants to celebrate by reminding you that pizza boxes are recyclable in Canada.

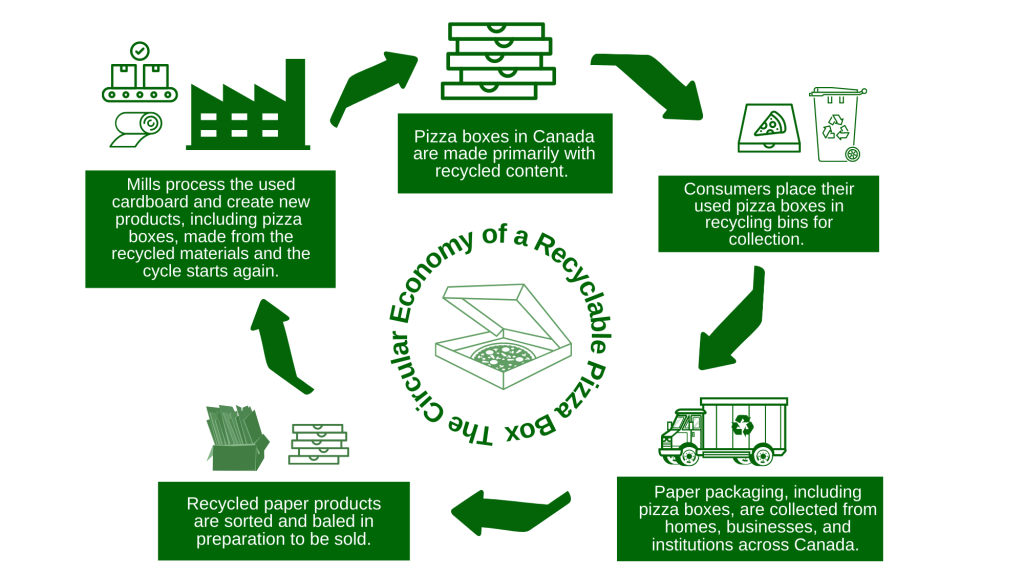

Pizza boxes are typically made from corrugated board, and in Canada, corrugated board is made mostly from recycled content. So once that pizza is eaten and the box is empty and clean, pizza lovers can easily place it in their recycling bins. Once it is collected, it will be sent to a Material Recycling Facility (MRF) for processing, where it will get sorted, baled, and sold. And that recycled material will make its way back to our members’ paper packaging mills, where it will get remade into a new pizza box or another type of paper-based packaging.

Recycled pizza boxes are an important slice of the Canadian paper packaging industry’s circular economy.

Recycled content keeps valuable raw materials out of landfill and flowing for longer, reducing the need to extract virgin materials. The average recycled content for domestic shipments of containerboard – which is used to make corrugated board like pizza boxes – is 86.5%, according to PPEC’s 2020 Recycled Content Survey.

Thanks to the essential act of recycling, it is likely that your pizza box has had multiple lives, and we want that to continue. But unfortunately, there has been some confusion over the years when it comes to the recyclability of pizza boxes in Canada.

In the past, some have suggested that pizza boxes should not be placed in blue box recycling bins because of the grease and cheese scraps. But that’s not true. If you remove the food scraps (eat those crusts!) and any plastic (like that three-pronged pizza saver which is meant to prevent the box top from sagging, though some of those single-use plastic items are being banned in Canada), that corrugated pizza box is recyclable in Canada.

When it gets to the recycling mill, the empty pizza box goes into a pulper – which is like a big washing machine – where any non-paper materials are removed through a series of cleaning and screening processes. The paper fibres are then pumped onto a fast-moving screen to form paper or board. The rest of the process involves removing the moisture out of the paper or board so that it can be wound onto big rolls or cut into sheets, which are then shipped to a converter or a box plant, where it is remade into new paper-based packaging.

And as for that greasy residue on the box, the heat of the process usually gets rid of it. In a typical mill’s recycling process, the temperature of the paper sheet reaches up to 240 degrees Fahrenheit – well above 100 degrees Celsius, the boiling point of water and the temperature required for sterilisation – which gets rid of the grease. Though there is not much grease to begin with, as the average grease content of a pizza box found in the recycling stream is approximately 1-2% by weight level, according to WestRock’s Incorporation of Post-Consumer Pizza Boxes in the Recovered Fiber Stream Study.

Paper packaging is a successful recycling story in Canada and pizza boxes are no exception.

Not only do 96% of Canadians have access to recycling for corrugated boxes, as determined through an independent third-party study commissioned by PPEC, but Canadians actively do their part by recycling their boxes, as evidenced by high paper recovery rates in provinces with legislated paper packaging recycling programs. However, it should be noted that for some Canadian communities, composting paper packaging (including pizza boxes) may be more convenient, such as in Nova Scotia and Prince Edward Island, who are hundreds of kilometres from the nearest packaging recycling mill.

Happy National Pizza Day from PPEC, and don’t forget to recycle your empty pizza boxes so they can be recycled into new pizza boxes!